TFI Marine

SeaSpring

What is it?

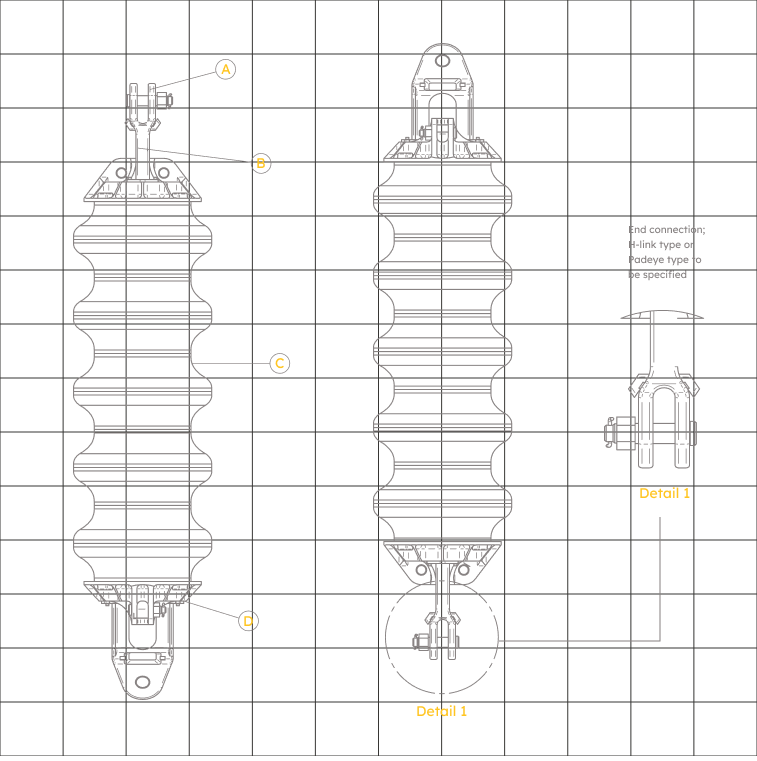

Fully tested under the most rigorous marine conditions, TFI Marine SeaSprings are polymer-based mooring components that enable mooring system designers to radically change the response of a mooring system. It consists of a durable, compressible, convoluted, ultra-strong polymer cylinder, encasing a fully marinised sliding metal structure.

How it works

The SeaSpring allows the platform response at its operating or survival loads to be tailored, resulting in substantially lower maximum loads on the mooring system. The mooring system configuration can be optimised depending on the desired performance, i.e., maximum load reduction, fatigue reduction, footprint reduction, etc.

What is it?

Fully tested under the most rigorous marine conditions, TFI Marine SeaSprings are polymer-based mooring components that enable mooring system designers to radically change the response of a mooring system. It consists of a durable, compressible, convoluted, ultra-strong polymer cylinder, encasing a fully marinised sliding metal structure.

How it works

The SeaSpring allows the platform response at its operating or survival loads to be tailored, resulting in substantially lower maximum loads on the mooring system. The mooring system configuration can be optimised depending on the desired performance, i.e., maximum load reduction, fatigue reduction, footprint reduction, etc.

SeaSpring

Lifetime extension

SeaSprings reduce fatigue by over 30%, extend the lifetime of the mooring system, and lower maximum loads on the mooring system.

Peak Load Reduction

Our technology reduces mooring loads by over 50%, enabling a reduction in MBL requirements for all mooring line components.

Flexible Mooring

TFI SeaSprings of varying size and stiffness can target different sea states in a mooring line, reducing ULS load and operational scenario fatigue.

Transform your mooring operations with a more sustainable and efficient solution

TFI SeaSprings are compatible with all mooring configurations, line type and wind platform. This comprehensive compatibility empowers you to enhance the performance and reliability of your mooring system across any setup, ensuring optimal results in the ever-evolving field of offshore wind energy

-

Load Reduction

TFI Marine SeaSpring's innovative technology reduces the peak load by up to ~50% and the fatigue by ~30%, increasing the efficiency and reducing maintenance costs

-

Installation

The SeaSpring offers the client the opportunity of selecting a cost effective installation process saving both time and money

-

Fatigue

Our technology reduces the impact of fatigue on the structure by ~20% to ~30%, increasing its reliability and lifespan

-

Footprint

TFI Marine SeaSpring's product delivers high performance while reducing the environmental impact with a reduced footprint of up to 70%

-

Lifetime

TFI Marine's Seaspring provides the opportunity of reducing footprint by up to ~70%, reducing the environmental impact of the mooring system on the seabed

-

Material

Our product utilises smaller and lighter materials that maintain high strength and durability, making transportation and installation easier without compromising performance

-

Recyclable

TFI Marine SeaSpring is manufactured using materials that are 100% recyclable, thus promoting a more sustainable future and reducing waste

-

DNV Certified

TFI Marine has received certification from DNV

-

AquaStructures Certified

TFI Marine has received the NYTEK23 / NS9415 certification

The Floating Wind Mooring Challenge

The SeaSpring Solution

Mooring without SeaSpring

Mooring without SeaSpring

Mooring with SeaSpring

THE BUILD

SCALING

SeaSprings can be scaled to whatever MBL is required. The polymer design determines the load at which the SeaSpring delivers maximum performance for load & fatigue reduction. This is separate from the MBL which is determined by the metal which is determined by the metalwork.

Polymer designs for FOW typically range from ~4000kN to ~7000kN, depending on the platform and number of mooring lines. The MBL of the structure is independent of the polymer, allowing the SeaSprings MBL to match the minimum requirements for the mooring configuration, irrespective of the polymer design

DNV-OS-E302: Offshore Mooring Chain: 2022

Contact Us

For more information on the SeaSpring contact our sales and technical team.